Corten Steel: Where Strength Meets Timeless Design

In architecture and industrial design, few materials manage to balance durability and visual appeal as effectively as corten. Known for its distinctive weathered surface and impressive structural performance, this specialised steel has become a favourite among architects, engineers, and designers seeking a material that evolves beautifully over time. Rather than hiding from the elements, corten embraces them, developing a natural patina that protects the steel beneath while adding character to every application.

Corten’s popularity is rooted in both function and form. Its ability to resist atmospheric corrosion reduces maintenance requirements, making it an efficient choice for outdoor structures. At the same time, its earthy, rust-like finish brings warmth and texture to spaces that might otherwise feel cold or industrial. This dual personality has allowed corten to move effortlessly between heavy infrastructure projects and refined architectural statements.

Understanding Corten Steel and Its Unique Properties

At its core, corten steel is a weathering steel alloy designed to form a stable, protective oxide layer when exposed to the environment. Unlike conventional steel, which continues to corrode unless treated or painted, corten’s surface rust actually acts as a shield. Once the patina stabilises, it slows further corrosion, extending the lifespan of the material.

This self-protecting quality is achieved through a carefully balanced chemical composition that includes elements such as copper, chromium, and nickel. These additions enhance corrosion resistance while maintaining structural integrity. The result is a steel that performs exceptionally well in outdoor conditions, particularly in environments where moisture and temperature changes are common.

The Visual Appeal of Weathered Steel

One of Corten’s most celebrated characteristics is its appearance. As the steel weathers, it develops a rich palette of tones ranging from deep oranges to dark browns. This natural variation ensures that no two installations look exactly the same, giving designers a material that feels organic and alive.

In architectural contexts, corten introduces warmth and contrast. It pairs beautifully with glass, concrete, timber, and greenery, making it a versatile choice for both modern and traditional designs. The evolving surface finish also tells a story over time, reflecting the environment and conditions in which it exists.

Applications Across Architecture and Construction

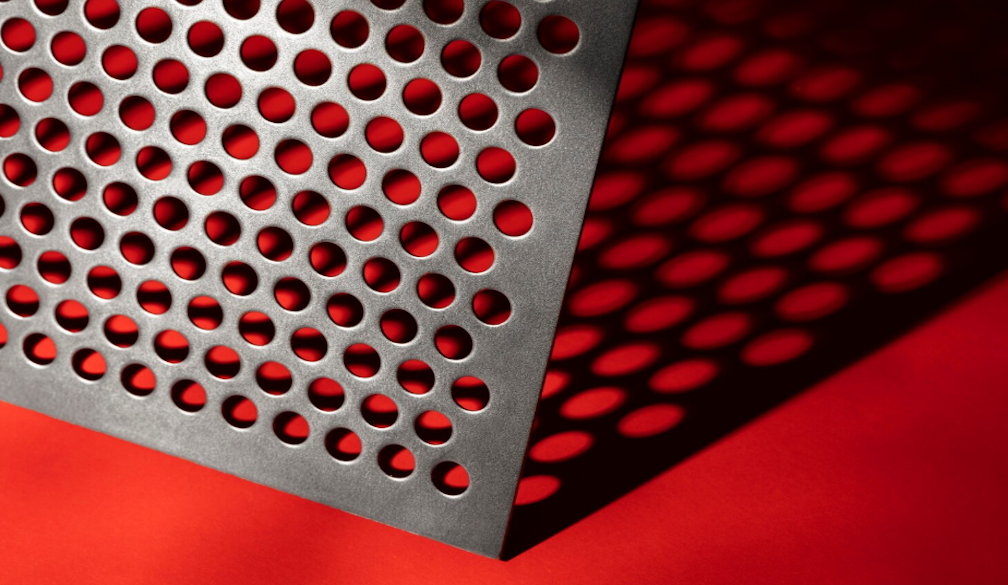

Corten steel is widely used in architectural façades, bridges, retaining walls, and public art installations. Its strength and corrosion resistance make it suitable for structural elements, while its appearance lends itself to decorative features. In urban environments, corten is often chosen for cladding and screens, where it provides visual interest without the need for ongoing coatings or treatments.

Landscape architecture also benefits from Corten’s durability and aesthetic qualities. Planters, edging, and garden structures made from corten integrate seamlessly into natural surroundings. Over time, the steel’s patina complements soil, plants, and stone, creating cohesive outdoor spaces that feel grounded and intentional.

Industrial and Infrastructure Uses

Beyond design-focused applications, corten steel plays an important role in infrastructure. Bridges, rail components, and industrial structures benefit from its resistance to weather-related wear. Reduced maintenance requirements translate into long-term cost savings, particularly in large-scale projects where repainting or protective coatings would be expensive and disruptive.

In these contexts, performance is paramount. Corten’s ability to withstand harsh conditions without compromising structural integrity makes it a reliable choice for engineers and project managers seeking longevity and efficiency.

Maintenance and Longevity Considerations

One of the key advantages of corten steel is its low-maintenance nature. Once the protective patina has formed, the steel generally requires minimal intervention. However, proper design and installation are essential to ensure optimal performance. Adequate drainage and airflow help the patina stabilise evenly, preventing issues such as runoff staining on adjacent surfaces.

While corten is highly durable, it is not entirely maintenance-free in every environment. Coastal or highly polluted areas may require additional consideration, as salt and contaminants can affect the patina’s stability. Understanding these factors during the design phase helps ensure the steel performs as intended over its lifespan.

Sustainability and Environmental Benefits

Corten steel aligns well with sustainable building practices. Its long service life reduces the need for replacement, conserving resources over time. The absence of paints or coatings also eliminates the environmental impact associated with ongoing treatments and maintenance.

Steel itself is highly recyclable, and Corten is no exception. At the end of its life cycle, it can be repurposed or recycled, contributing to circular economy principles. For projects aiming to balance durability, aesthetics, and environmental responsibility, Corten offers a compelling solution.

Design Flexibility and Customisation

Another reason for Corten’s widespread adoption is its adaptability. It can be fabricated into a wide range of shapes and forms, allowing designers to explore creative possibilities without sacrificing performance. From sleek panels to intricate screens, corten accommodates both bold statements and subtle accents.

Its compatibility with modern fabrication techniques ensures precise results, whether the project calls for large structural elements or finely detailed features. This flexibility makes corten suitable for projects of varying scales and complexities.

Why Corten Steel Continues to Grow in Popularity

The enduring appeal of corten steel lies in its ability to age gracefully. In a world where many materials degrade or require constant upkeep, corten stands out by improving with time. Its evolving surface becomes a visual record of exposure and experience, adding depth and authenticity to built environments.

As architects and builders seek materials that offer both performance and personality, corten remains a standout choice. Its combination of strength, resilience, and aesthetic richness ensures it will continue to shape contemporary design and infrastructure for years to come.